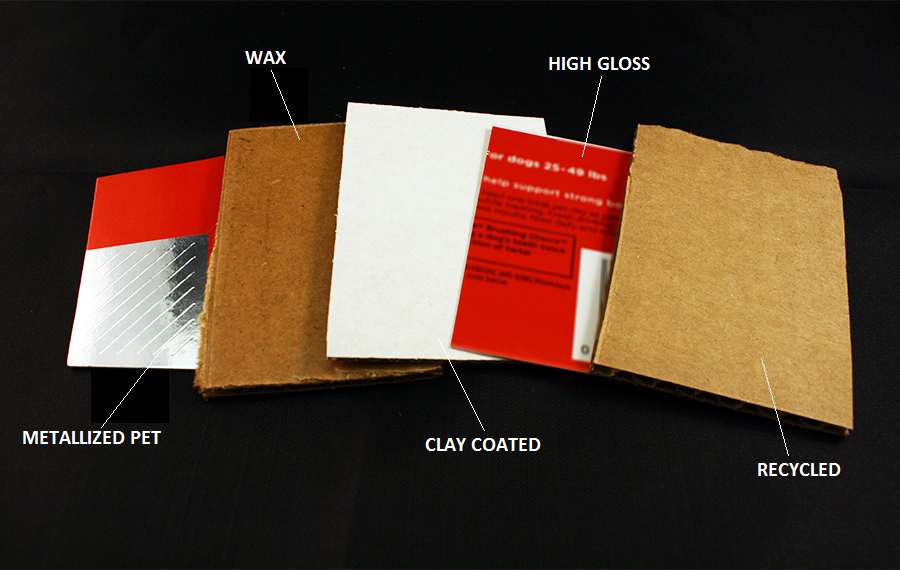

Some substrates are more difficult to bond than others, particularly those in the food packaging industry. Many of our customers use corrugated packaging that has a wax curtain coating or is wax impregnated, making adhesion more difficult to achieve. Without the right adhesive, you may face pop-opens and other adhesion failures, increasing your costs. At RS Industrial, we ensure you get the best adhesive for your specific food packaging application.

Wax acts as a moisture barrier between the food product and its packaging. Since a wax curtain coating is concentrated on the surface of the substrate, it’s difficult for an adhesive to penetrate that surface and form a bond. On the other hand, wax impregnated contains wax throughout its fibers, making it slightly easier to bond. For these types of packaging, we would recommend an adhesive with a long open time so that it is able to penetrate through the wax.

Most corrugated packaging used today is also recyclable. Compared to virgin corrugated, recycled corrugated has shorter, more compact fibers. This makes it more difficult to accomplish a fiber-tearing bond.

We offer a full selection of adhesives ready to bond any of these substrates and more. By performing on-site testing at your facility or our internal lab, we can quickly recommend an adhesive solution that fits your specific food packaging application. To learn more about how we can help decrease your chances of pop-opens and increase your production, contact us at 1-800-844-1740 or info@rsindustrial.com. Let us take the guesswork out of your adhesive process!