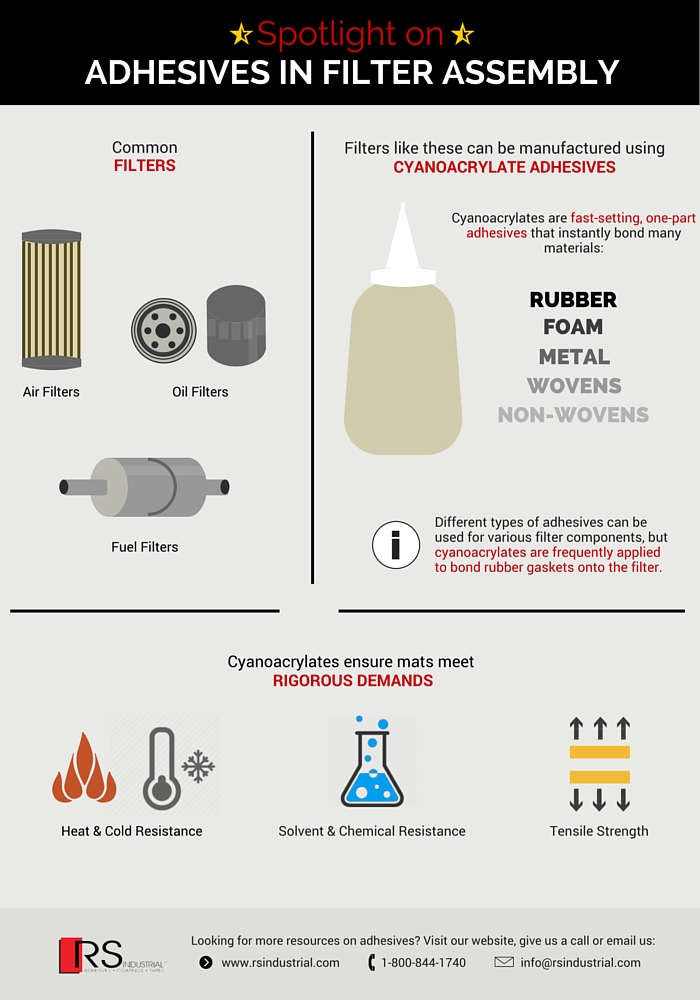

Application Spotlight: Filter Assembly with Cyanoacrylate Adhesives

Have you ever accidentally stuck your fingers together using a cyanoacrylate adhesive (aka “super glue”)? If the answer is yes, then it’s no surprise. Many of us have goofed up and done it at some point! Cyanoacrylates are incredibly strong and fast-acting. This makes them particularly ideal for bonding dissimilar materials.

Dissimilar materials are common in the assembly industry, so we’ve been highlighting a few applications where cyanoacrylates can be used to bond them. If you missed last week’s post, we discussed how cyanoacrylates can be used in mat manufacturing. This application is just one good example of where cyanoacrylates can be used to form durable bonds to rubber as well as other materials such as foam, metal, wovens and non-wovens.

This week we’re highlighting another great application for cyanoacrylates: filter assembly. Many filters require rubber gaskets be installed to prevent leakage while under compression. Although different types of adhesives can be used for assembling the different components of filters, cyanoacrylates are frequently used to bond rubber gaskets during filter assembly.

Types of filters that commonly use cyanoacrylates:

• Oil filters

• Air filters

• Fuel filters

These filters are placed in some of the harshest conditions, so it’s important that they meet demands such as:

• Heat and cold resistance

• Solvent and chemical resistance

• Tensile strength

Cyanoacrylates ensure strong bonds that allow products such as filters to meet these rigorous demands. To find out if a cyanoacrylate adhesive would be the best solution for your assembly, give us a call at 1-800-844-1740 or email us at info@rsindustrial.com. One of our technical service analysts would be happy to discuss your specific application and needs.