Throughout the day, your priority is making sure everything runs smoothly and efficiently in the plant to yield maximum production. Although a small part of the overall process, this includes your hot melt operation.

There are many contributing factors that can impact the performance of your hot melt, but knowing the best practices that every hot melt user should follow will increase your chances of getting the best results for your application.

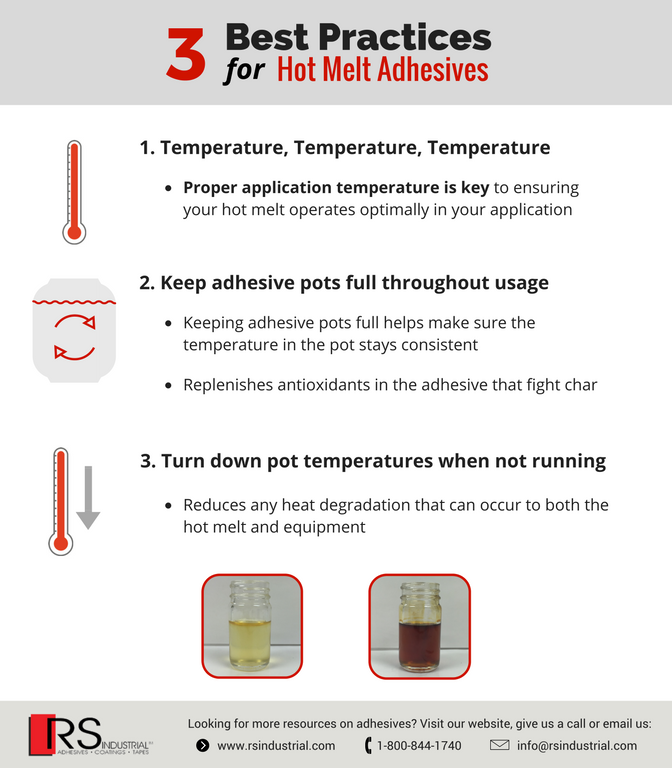

Follow these 3 tips to ensure your hot melt performs optimally:

3 best practices to make sure your hot melt adhesive performs optimally.

1. Apply adhesive at the proper temperature: Temperature is an extremely important variable for the success of your hot melt application. If the adhesive is too hot, it will take longer to bond and may result in what is best described as “chewing gum failure” (learn more here). If the adhesive temperature is too cool, it may set too early and result in a weak bond. This is known as pre-set. Follow your manufacturer’s TDS for the suggested application temperature range and adjust accordingly.

2. Keep adhesive pots full: Remember to keep your adhesive pots full during usage. When the adhesive level gets too low, hot spots and gel formation can occur, resulting in char. If you’re manually loading them, it can be easy to forget to refill your pots. Having an automated filling system to replenish adhesive on demand and a level control system to monitor the adhesive level will ensure your pots stay full. This replenishes antioxidants in the adhesive, which fight char.

3. Turn down pot temperatures when not running: Since hot melt tanks, hoses and nozzles continuously undergo heat stress, they have the tendency to create char. Turn down the pot temperature when it’s not in use to reduce any heat degradation that can occur to both the hot melt and equipment. This will decrease the opportunity for charring to occur.

Following these best practices can help increase your productivity and decrease downtime in your plant. For more information or guidance on your hot melt process, contact us at 1-800-844-1740 or use the contact form below. Our technical service team is available 24/7 and will quickly respond to your inquiry.