You’ve packaged your product, sealed the box, and are ready to ship. You’re close to getting product out the door when you notice that the boxes have popped open. Unfortunately, pop-opens can cause downtime and increase your costs.

Case and carton failures can happen for a number of reasons. In this four-part series, we’ll address the most common reasons for failure – starting with adhesive pre-set.

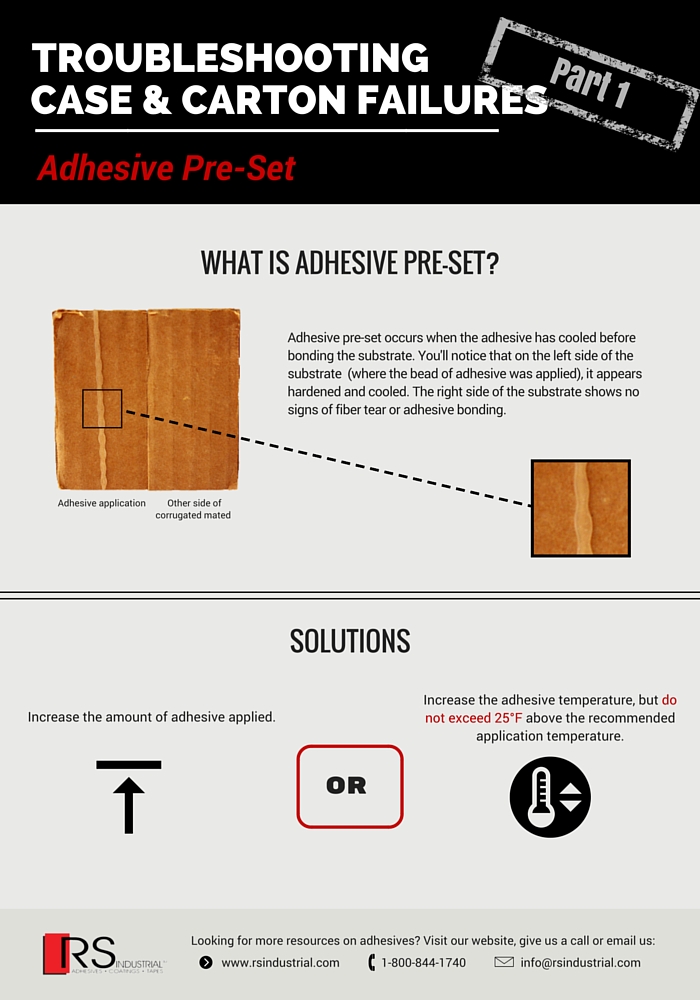

Part 1: What is Adhesive Pre-Set?

When hot melt adhesive is applied to a surface and the substrates are compressed, a bond is typically formed. But sometimes, the adhesive can set before the substrates are mated. This happens when equipment open time is longer than the adhesive’s open time at current settings. Open time is the time after the adhesive is applied during which a proper bond can be made. If the substrates aren’t compressed prior to this time, it is likely that adhesive pre-set will occur.

To resolve adhesive pre-set, you have two options you can try:

- Increase the amount of adhesive applied.

- Increase the adhesive temperature, but do not exceed 25°F above the recommended application temperature.

Taking either one of these actions should eliminate the issue, but we always recommend you work with your adhesive supplier to correctly diagnose the issue and find a solution. For more information, contact us at 1-800-844-1740 or use the contact form below. Our adhesive experts are available 24/7 to provide technical support.